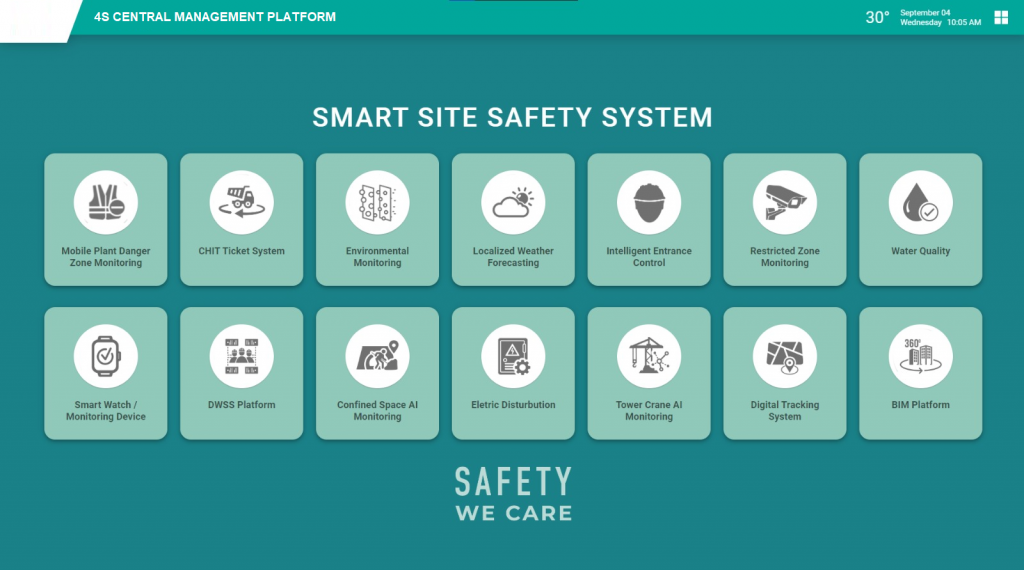

Smart Site Safety System (4S) consists of three parts, including the Intelligent Safety System, Communication Network, and Central Management Platform. The Intelligent Safety System integrates various safety devices and sensors, such as smoke and fire detectors, temperature and humidity monitors, and hazard alert systems. These devices and sensors are connected to the Central Management Platform through a wireless network, enabling the platform to collect and analyze data in real-time, provide timely alerts, achieve comprehensive monitoring, and centralized management. Through the 4S Safety Intelligent Construction Site System, site managers can have a more comprehensive understanding and control over the safety status of the construction site, respond promptly to potential safety risks, and enhance the safety and management efficiency of the construction site.

Central Management Portal (CMP)

The Central Management Platform (CMP) is used to respond to, manage, and record signals/alerts issued by the Smart Site Safety System (4S). Users can directly monitor the progress and performance of the construction online. These signals/alerts are transmitted to different screens on the central platform in the form of videos, audio, images, and data, facilitating the required data analysis.

Safety Data Statistics Dashboard

Comprehensive recording of the number of workers on site, the frequency of violation categories, and analysis of subcontractor violations, and more.

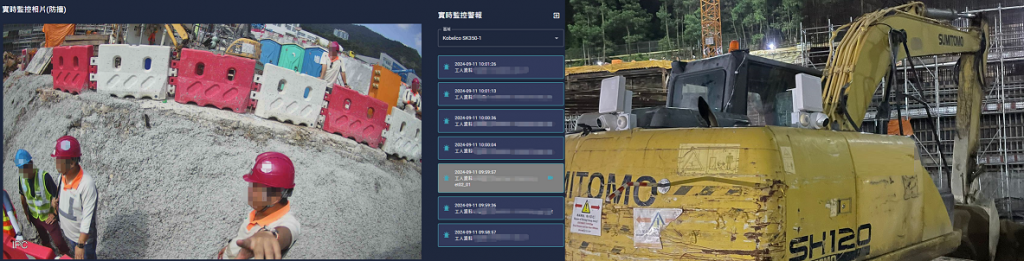

Alert system for unsafe behaviors/dangerous situations in the hazard zone of mobile machinery operation system

In this system, sufficient sensors are installed on the chassis of mobile machinery and on large movable machinery (such as excavators, crawler cranes, and mobile cranes) to ensure full 360-degree detection of the danger zone around the machine. When machine operators and any workers are in the vicinity of the danger zone and there is a risk of being crushed or struck by moving machinery parts, the system will issue an alert, and the CMP will also receive relevant alert data in real time.

Artificial Intelligence Security Surveillance System

Artificial Intelligence network cameras and related artificial intelligence processors, this system is used to detect and identify unsafe conditions on construction sites and categorize them, including:

(i) Unauthorized individuals entering restricted areas, danger zones, lifting areas, and no-parking zones;

(ii) Workers approaching construction vehicles or machinery;

(iii) Workers potentially at risk of collision with construction vehicles or machinery;

(iv) Detecting whether construction vehicle and machinery operators are fatigued, distracted, or lack concentration during construction;

(v) Workers and other personnel not wearing appropriate personal protective equipment, including helmets and reflective vests;

(vi) Lifting heights exceeding authorized limits; and

(vii) Workers working at heights without wearing safety harnesses or using suitable work platforms.

Intelligent Monitoring System for Workers and Frontline Personnel on Construction Sites

To facilitate effective construction, employees and frontline personnel are equipped with smart devices such as smart helmets, smart wristbands, and more. These smart devices can connect to the central system through mobile communication, wireless networks (WiFi), Narrowband Internet of Things (NB-IoT), Low Power Wide Area Networks (LoRa), etc. The smart devices offer the following functions:

(i) Tracking the movements of workers and frontline personnel indoors and outdoors at different times and locations;

(ii) Real-time detection of stationary status;

(iii) Real-time monitoring of body temperature and heart rate;

(iv) Detecting moving equipment or vehicles and sending alerts to workers and machinery/equipment operators; and

(v) Detecting unauthorized individuals entering restricted areas and sending alerts to workers and machinery/equipment operators.

Implementing access control to hazardous areas using an electronic lock system

This system prevents unauthorized individuals from accessing locked covered passages, gateways, railings, and areas leading to hazardous zones within the construction site (such as electrical boxes, floor openings equal to or greater than 500mm x 500mm, entrances to confined spaces, elevator shafts, etc.). Gates equipped with an electronic lock system only allow authorized personnel to enter and exit, requiring authorized individuals to use an electronic key containing personal information.

Digital tracking system for construction machinery, power tools, and ladders

This system enables real-time online tracking of all construction machinery, power tools, and ladders, updating information on test certificates, inspections, checks, and maintenance regularly. Each piece of machinery, power tool, and ladder used on the construction site is assigned a unique code. By scanning the code with a mobile device, information from the database is displayed on the mobile device, including equipment test certificates, inspection records, maintenance information, and inspection reports.

Digital permit to work system

Digital permit to work system for high-risk operations allows users to submit work permit applications in real-time via mobile devices for approval by supervisors or management. The system also includes tracking capabilities to record activities when engaging in the following high-risk tasks:

(i) working in confined spaces;

(ii) working in environments with electrical hazards;

(iii) working in elevator shafts;

(iv) where there are mobile cranes, heavy machinery, and pile drivers operating or moving on the ground;

(v) working in hot environments;

(vi) working off the ground using ladders;

(vii) operating tower cranes, mobile cranes, crawler cranes, similar lifting equipment, or mechanically operated lifting operations.

Real-time information on corresponding work permits/operation permits and operational statuses will be displayed on mobile devices.